Field Cured Concrete Test Specimens

There are several methods of curing concrete test specimens, such as concrete cylinders, depending on how the strength results are to be used. When producing test specimens that are used to estimate the current strength of the concrete placement, the test specimens should be field cured. But note that field-cured test specimens should NEVER be used for concrete acceptance (i.e. "pay" cylinders) or for quality control.

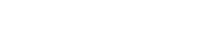

Field cured specimens are molded and stored on, in, or as nearby the concrete placement as possible in order to estimate the effects of environmental conditions on strength gain. For example, hot concrete gains strength more quickly than cold concrete since hydration occurs at a faster rate at higher temperatures. Therefore if standard cured, temperature controlled test specimens provide a poor representation of in-place strength gain due to having vastly different temperature histories. Thus test specimens for in-place strength estimates are cured in the field so they experience similar environmental conditions to that of the placement.

Despite their limitations, field-cured cylinders can produce useful strength estimates IF the curing conditions accurately reflect what is experienced by the in-place concrete. While this sounds simple (e.g. just cure the test specimens at the jobsite in the same weather conditions) obtaining accurate results can be challenging. This is because the actual temperature and moisture histories MUST be similar to generate an accurate representation of hydration and strength gain. In a thin geometry such as an elevated deck, simply placing field-cured cylinders on the deck may generate comparable temperatures. However, as structures increase in dimensions, and the effects of formwork are considered, relatively small concrete test specimens (e.g. 6 inch x 12 inch cylinders) tend to react to environmental conditions much more quickly than the in-place counterpart. This results in inconsistencies between the strength of the test specimen and placement.

Despite the accuracy limitations of using field-cured test specimens to estimate in-place concrete strength, this was the most commonly used estimate used by the concrete industry for a century. Today, however, more accurate and convenient strength estimation techniques are available such as the concrete maturity methods defined in ASTM C 1074,

More on using Concrete Maturity Methods to estimate in-place concrete strength.

More on using Concrete Maturity Methods to estimate in-place concrete strength.

RESOURCES

ASTM C31 - SIcerts ON CREATING SPECIMENS IN THE FIELD